Diesel Centar

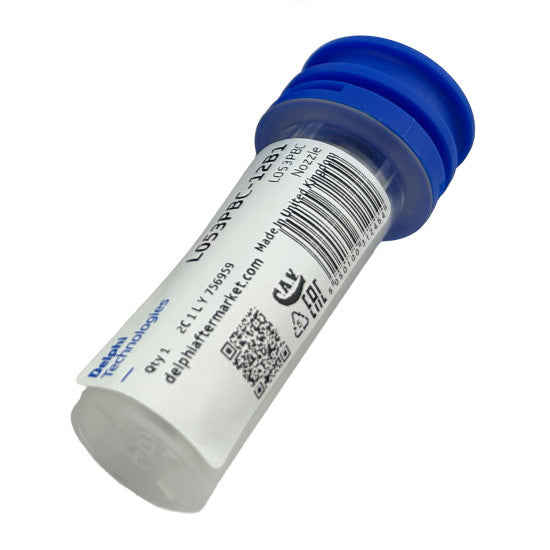

L053PBC

L053PBC

Couldn't load pickup availability

DELPHI INJECTOR NOZZLE: L053PBC – FULL SPECIFICATION

I. Key Identification & Compatible Injectors

Nozzle (Injector Tip) P/N: L053PBC

Nozzle Type: Common Rail (often associated with Delphi E3 injectors, can also be E1 or E2 series)

System Manufacturer: DELPHI Common Rail Diesel Injection System.

Compatible Injector Assembly P/N(s):

- Delphi Injector Reference: BEBJ1A00001 / BEBJ1A00101 / BEBJ1A00201 / BEBJ1A00501

- OEM Injector Reference (DAF): 1661060 / 1725282 / 1742535 / 1820820 / 1905002

- OEM / Vehicle Manufacturer: DAF

- Typical Applications (with HP / kW):

• DAF CF85 – 430 HP / 316 kW, 480 HP / 353 kW

• DAF XF105 – 460 HP / 338 kW, 510 HP / 375 kW

II. Vehicle / Engine Application & Technical Data

Primary Vehicle Application: Heavy commercial vehicles (trucks) equipped with Delphi Common Rail diesel injectors.

Engine Type: Inline-6 / V6 Common Rail Diesel, Euro 4 / Euro 5 / Euro 6 compliant depending on model

Injector Technology: Delphi Common Rail Solenoid Injector.

Nozzle Type: L053PBC — precision high-pressure nozzle for efficient atomization and combustion.

Technical Characteristics:

- Material: High-strength tool steel

- Number of Holes: Engine variant dependent (~5–7)

- Hole Diameter: ~0.150–0.200 mm

- Spray Angle: 140–150°

- Operating Pressure: 1600–2000 bar

- Fuel Compatibility: EN 590 Diesel / B7 Biodiesel blends

- Performance Features: Optimized for high-load diesel engines, stable spray pattern, low emissions, and long service life

III. Critical Technician Notes (MUST-DO)

1. Clean Installation: Clean nozzle thoroughly (ultrasonic cleaning recommended) before installation.

2. Sealing Components: Always replace O-rings, copper washers, and seals; do not reuse old parts.

3. Injector Mounting: Follow OEM torque and alignment specifications.

4. Post-Installation Testing: Perform leak-back or test-bench spray tests to verify proper spray pattern and no leaks.

5. Calibration / Coding: Use DAF or Delphi diagnostic tools if injector coding is required.

6. Fuel Quality Notes: Use clean, high-quality diesel; replace fuel filters during service.

7. Storage & Handling: Store nozzles in a clean, dry environment; protect tip from mechanical damage.

8. Common Fault Symptoms: Hard start, rough idle under load, black smoke, loss of power, or excessive fuel return flow.